High Speed Electrical Silicon Steel Reactor Core Cutting Machine

Electrical Silicon Steel Reactor Core Cutting Machine I Description of electrical silicon steel reactor core cutting mac;

Basic Info

| Model NO. | JN-3002S |

| Power Source | Electric |

| Cutting Mode | Motorized Blade Cut |

| Suitable Silicon Steel Strip Width | 30-300mm |

| Suitable Silicon Steel Strip Thickness | Max. 0.6mm |

| Material Feeding Method | Delta Servo Motor |

| Material Feeding Speed | Max. 100m/Min |

| Cutting Speed | 100-150 Cuts Per Minute |

| Cut to Length Precision | +/-0.02mm |

| Burr Height | Less Than 0.02mm |

| Cutting Blade | Carbide Alloy |

| Blade Life | 1,200,000 Times Before Grinding |

| Control System | PLC Control + HMI |

| Transport Package | Wooden Case |

| Specification | 1600 x 800 x 1200mm (main machine) |

| Trademark | Zhenhuan |

| Origin | China |

| HS Code | 8462319000 |

| Production Capacity | 10 Sets Per Months |

Product Description

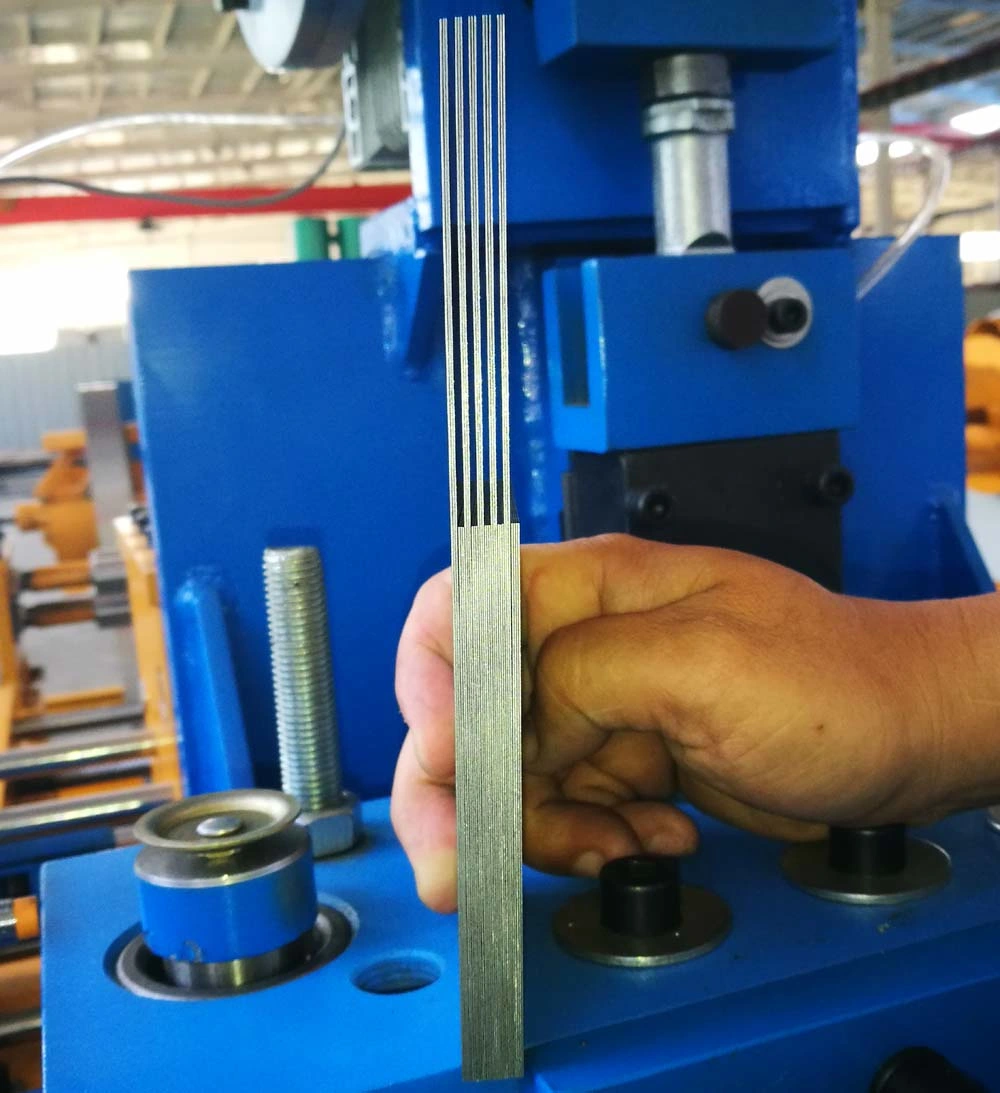

Electrical Silicon Steel Reactor Core Cutting Machine I Description of electrical silicon steel reactor core cutting machineThis machine is specially designed for cutting silicon steel coils into silicon strips for transformer cores, welding machine cores, and reactor cores.This machine is specially designed for cutting min. 0.1mm thick CRGO electrical silicon steels from Europe.

II Detailed information of electrical silicon steel reactor core cutting machine:

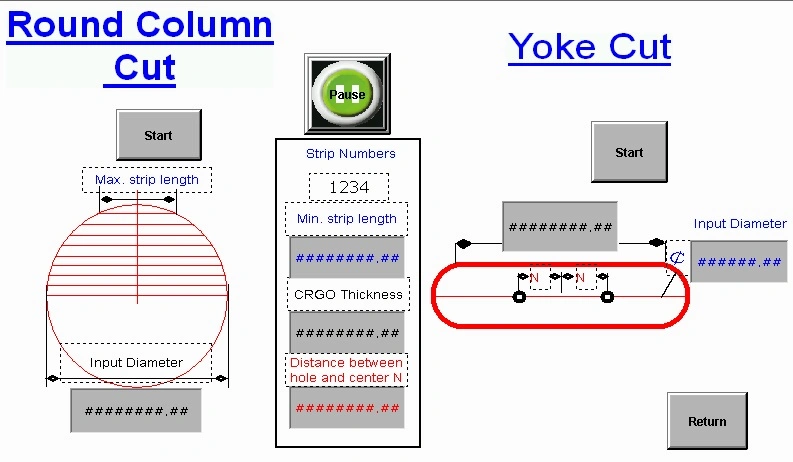

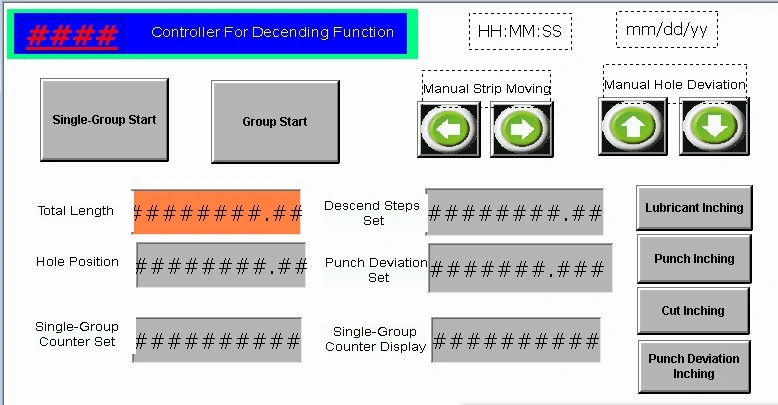

2.1 Inverter-controlled decoiler:- Motor power: 1.5kW- Max. Coil weight: 1000kg- Max. Coil width: 500mm- Coil inner diameter: 480-520mm- Coil outer diameter: 1200mm2.2 High speed feeding machine- Servo motor driving: Delta servo motor, 4.5kW- Feeding precision: +/-0.02mm- Feeding speed: Max. 100m/min- Feeding roller material: Special mould steel in high hardness2.3 Cutting device- High speed cutting, 100-150 times per minute- Cut-to-length tolerance: +/-0.02mm- Cutting motor power: Delta servo motor 2kW- Cutting blade: carbide alloy, life more than 2,000, 000 times before grinding- Quantity and length are pre-set on the touch screen2.5 Run-out table: Prepared by Buyer, for collecting cut pieces2.6 Control system- Delta PLC- Delta touch screen 5.7"- Quantity, length, speed, hole numbers, hole positions can be pre-set on the touch screen- Special round column cutting function:

- Special descending cutting function suitable for gap wound core production:

Item | Data |

Suitable silicon steel strip width | 30-300mm |

Max. silicon steel thickness | 0.1-0.6mm |

Cut to length | 1-999999mm |

Cut to length tolerance | +/-0.05mm |

Burr height | Less than 0.02mm |

Servo feeding speed | Max. 100m/min |

Cutting speed | 100-150 cuts per minute |

Dimension | About 800 x 1600 x 1200mm (main machine) |

Weight | About 900kg |

Our workshop facilities ensuring silicon steel reactor core cutting machine quality:

Our Nantong Zhenhuan Trade is specialized in transformer making machines for more than 18 years. We have certified by SGS, TUV and BV for our professional and faithful service on NC silicon steel straight cutting machine. We have sold NC silicon steel straight cutting machine to UK, Germany, Viet Nam, Thailand, Pakistan, Bangladesh and India. Kindly please contact us for best price of NC silicon steel reactor core cutting machines.

You may also like

Send inquiry

Send now