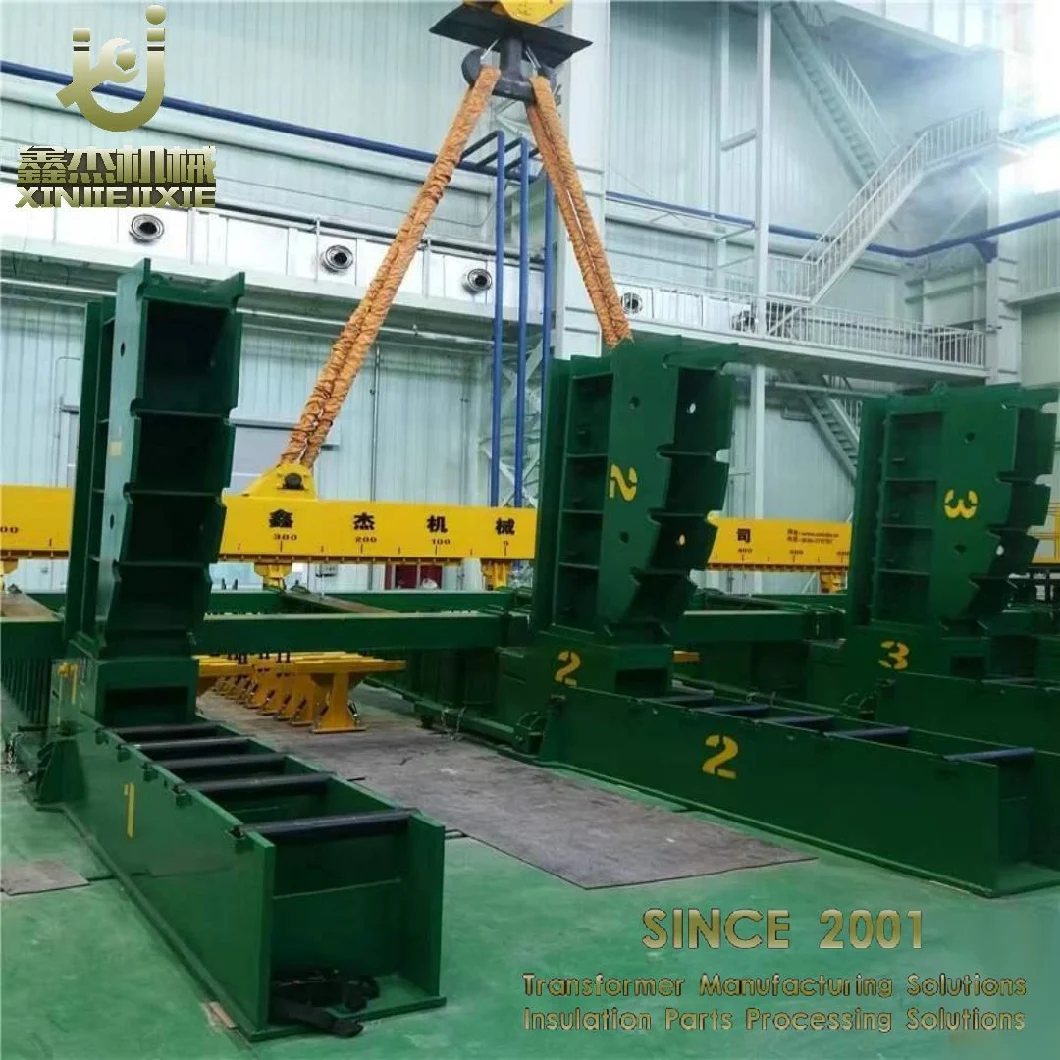

Transformer Core Stacking Table, Cores Assembling & Mounting.

Overview Machine usage The utility model is suitable for stacking and overturning iron cores of large and medium-sized t;

Basic Info

| Model NO. | FT |

| Trademark | ZHONG XINJIE |

| Origin | Shandong China |

| HS Code | 84289090 |

| Production Capacity | 15 |

Product Description

Machine usage

The utility model is suitable for stacking and overturning iron cores of large and medium-sized transformers.(1) It is used for the process with and without the iron yoke(2) Applicable to: three-column iron core (three groups of platforms), five-column iron core (five groups of platforms) turnover and iron discharge Main models:

FT02,FT05,FT10,FT20,FT30,FT50,FT80,

FT100,FT150,FT200,FT250,FT350,FT450 t

Main feature

(1) The building blocks combined structure is assembled according to the window size of the iron core, which is not limited by the diversification of window size and has strong adaptability.

(2) No special pit and foundation are required, no operation space is occupied, and the economy is good.(3) Strong turnover capacity, no additional energy is required except for workshop driving. So as to save energy, reduce auxiliary equipment investment and basic investment, and have a good performance-price ratio.(4) Safe and stable turnover, good synchronization, no deformation of iron core and high reliability.(5) The center distance is adjustable, and the table size is designed according to customer requirements.(6) During turnover, the overall deformation of the table is less than 3mm, and the perpendicularity of the stacking table and the turnover beam is less than 2mm before and after turnover.(7) The use of international advanced design software for finite element analysis ensures sufficient strength and stiffness. Hot rolled section steel or low carbon steel welded structure is adopted. In order to ensure flatness, key positions are machined. For welded structures, aging treatment shall also be carried out. A turnover leg is installed on the longitudinal beam. Opening the leg after the iron core is turned 90 ° can prevent the iron core from turning over stably.Detailed Photos

Company Profile

Factory photo

Please feel free to contact us if you are interested in any products or have any questions.

You may also like

Send inquiry

Send now