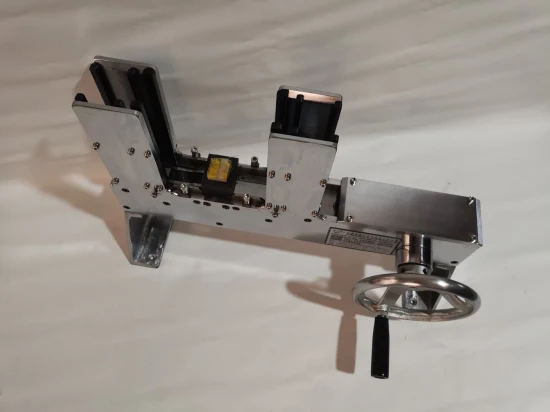

Manual Ei 48 Transformer Core Filling Machine/ Ei Stacking Machine

Overview Package size per unit product 100.00cm * 32.00cm * 42.00cm Gross weight per unit product 47.500kg Semi-automati;

Basic Info

| Function | Abrasion Resistance, Lubrication, High Temperature Resistance, Anti-Corrosion, Anti-Cold |

| Demoulding | Manual |

| Condition | New |

| Certification | RoHS, ISO, CE |

| Warranty | 24 Months |

| Automatic Grade | Semiautomatic |

| Installation | Desktop |

| Driven Type | Manual |

| Daily Output | Ei Inserts: 800~1500 Pieces |

| Transport Package | Paper Carton with Wooden Cases |

| Trademark | Windoo |

| Origin | China |

| HS Code | 8479811000 |

| Production Capacity | 5000 |

Packaging & Delivery

Package size per unit product 100.00cm * 32.00cm * 42.00cm Gross weight per unit product 47.500kgProduct Description

Semi-automatic EI chip inserter Stacking Machine For Transformer

Stacking machine For electronic transformer industry chip inserter, common specifications are:El series inserting machine (low-frequency transformer, power supply transformer, meter transformer, etc.) EI single-sided stacking insert (argon arc welding products)E-piece stacking plug (electromagnet PFC, transformer, etc.), pneumatic single-push chip machine EE plug-in, common in 14.16.19 and other models El type 2/3-chip whole-stack plug-in EI three-phase transformer plug-in UI plug Chip machineEl series double insert manual/electric inserter

Product Parameters

| Model | A | B | Machine size | Package size | Net weight |

| EI28 | 28 | 23 | 410×170×300mm | 410×170×300mm | 13kg/19kg |

| EI35 | 35 | 29.5 | 440×130×290mm | 550×240×330mm | 15kg/21kg |

| EI41 | 41 | 33 | 440×130×290mm | 550×240×330mm | 15kg/21kg |

| EI48 | 48 | 40 | 480×140×290mm | 550×240×330mm | 15kg/21kg |

| EI57 | 57 | 47.5 | 540×150×290mm | 630×260×380mm | 15kg/22kg |

| EI60 | 60 | 50 | 650×125×350mm | 680×155×380mm | 16kg/23kg |

| EI66 | 66 | 55 | 560×160×340mm | 630×260×380mm | 17kg/25kg |

| EI76 | 76 | 63.5 | 600×170×360mm | 840×330×440mm | 28kg/38kg |

| EI86 | 86 | 71 | 700×180×380mm | 840×260×400mm | 34kg/43kg |

| EI96 | 96 | 80 | 810×190×380mm | 840×260×400mm | 37kg/47kg |

| EI105 | 105 | 87.5 | 870×175×380mm | 900×205×410mm | 42kg/52kg |

| EI114 | 114 | 95 | 870×205×280mm | 920×280×410mm | 46kg/58kg |

| EI133 | 133 | 111 | 950×270×370mm | 1000×320×420mm | 47.5kg |

Application1. Suitable for low-frequency transformer silicon steel sheet inserts,2. Main models: EI-28, EI-35, EI-41, EI-48, EI-57, EI-66, EI-76.2, EI-85.8, EI-96, EI-105, EI-114, EI -133.2, EI-150Models can be customized according to customers: EI-24, EI-30, EI-32, EI-36, EI-38.4, EI-42, EI-54, EI-60, EI-74, EI-78, etc.3. Silicon steel sheet 0.35-0.5mm is universal and can be realized by adjustment!4. EI-28--66 type comes standard with one 3mm, 4mm L-shaped wrench each, and 2 I negatives (equipment accessories)5. Special steel special rotating parts, strong wear resistance, smooth hand wheel feel, high precision, can be inserted into annealed silicon steel sheet.Detailed Photos

Features of EI type chip inserter:• Ø This product is made of imported steel, with special treatment and precision machining, less wear, less failure, easy operation, long service life, and easy replacement of accessories.• Ø The E piece is not pulled upside down, and the I piece is smooth (0.35 and 0.5 pieces are applicable). The accessories wear little and the work efficiency is high.• Ø In addition to using E1 sheets of different thicknesses, the chip inserter does not need any adjustment and replacement of accessories;• Ø E-type and I-type are inserted into the coil shaft at intervals one by one.• Ø Regular EI-28 to EI-192.• Ø Other specifications can be customized according to customer requirements, customers only need to provide silicon steel sheets and skeletons. The operation method of EI type chip inserter:1. Put the silicon steel sheet into the charging trough, put the burr down, the silicon steel sheet with too thick burr and the uneven sheet, turn the hand wheel manually, and take out the first I sheet pushed out from left to right.2. Put the wound product skeleton balance on the debugged frame thimble.How to use and maintain the EI type inserter:1. Before using the chip inserter, manually turn the handwheel to check whether there are iron chips and sundries in the movable plate and the charging trough, and only after the air pipe is blown clean can the chip be inserted. If there is a card, it should be stopped immediately to discharge the fault before continuing to use, so as not to damage the frame and the parts of the inserter.2. If it is not used for a long time, take out the remaining silicon steel sheet, blow it clean with the air pipe, and then spray it with anti-rust oil on the rotating part of the whole machine. If possible, wrap it with a stretch film.

Why choose us?1. Environmental protection, low noise, and high efficiency;2. The storage capacity can be super large.3. You can choose different row directions, winding angles, and sectional angles.4. Photoelectric induction switch technology has high accuracy and an accurate number of rings.5. Stepper motor wiring and spacing can be accurately controlled;6. Products that can be tetragonal.Packaging & Shipping

Packaging & Shipping

General package(Paper carton or plastic bag): For small goods, Package it with form and pack paper to guarantee unbroken during the transport.Wooden case package: For larger scale goods such as machine equipment etc, we have a special skilled carpenter, who would make the proper wooden case with exact thickness, density, and length. The up arrow ↑marked on the outer wooden case. Buffer material would be put in the wooden case to prevent cracks and shock. We will inform you of the delivery note. You just need to wait for a phone call, then pick up the goods at the nearest logistic station. (Please let me know in advance if you want to get the goods at home.)Shipping:A. 3-5 workdays shipping from China by Air/Express(DHL, FedEx, UPS, EMS, etc.)B. 3-5 workdays shipping from UK Warehouse to European union countries.No need to pay for customs duties and VAT.C. 25-30 workdays shipping from China to Russian customers. No need to pay for customs duties and VAT.D. We can arrange shipment by sea. Minium CBM requirement : 1 CBMAfter Sales ServiceService

1. We provide you with a friendly English User manual or operating videos for free.2.24 hours of technical support by email or call.3. Warranty: 1 year free, 2-3 years cost price, and free technical support always.4. Free training to make sure you master the operation of our products.5. OEM/ODM accept. But the MOQ of OEM/ODM is 100 sets.Service tenetProvide you the best service with "fast + satisfactory + safe".Warranty period:12 months long after the user received the product.

You may also like

Send inquiry

Send now